Goal:

Our team develops execution software for manufacturing that is fully functional, user-friendly, efficient, and adaptable.

Modular Development:

Break down the software into modules (Production Tracking, Inventory Management, Quality Control, etc.) that can be scaled or replaced easily.

Real-Time Data Integration:

Implement IoT protocols (such as MQTT or OPC UA) to capture & process data from devices and sensors in real time. This is the heartbeat of manufacturing execution software, ensuring factory-wide visibility.

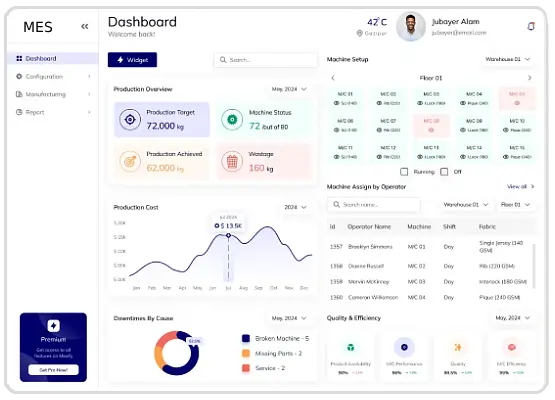

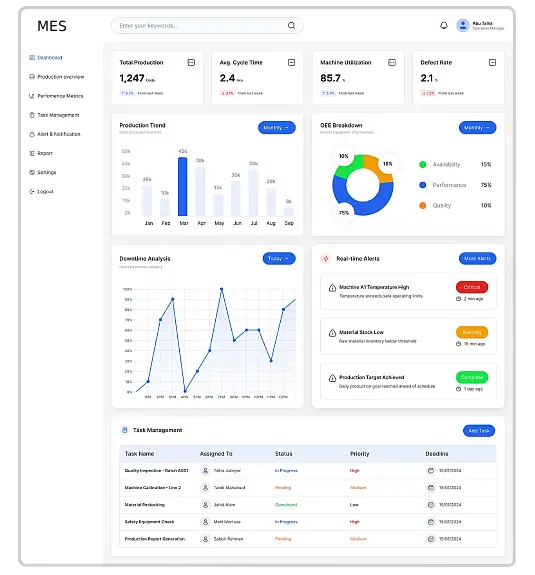

User-Centric UI/UX:

Our developers develop an intuitive dashboard and user interface. This allows factory workers, managers, plus operators to access real-time data quickly, with features (such as role-based access control & mobile support).

Custom Workflows & Automation:

Tailor workflows to your specific manufacturing processes. Automation tools will help streamline repetitive tasks, such as inventory tracking or quality checks, improve overall productivity, etc.